So, here we are, the moment you have all been waiting for: behold a working prototype of an insertable toy.

After building up the layered conductive and non-conductive silicone per my insertable design, the next challenge was getting a negative mold of a penis. My penis to be precise, because I wanted the first prototype to be of my own wang!

Turns out it’s a lot harder than you think to make a clone of your penis. I investigated doing a 3D scan using photogammetry, which could have worked but it really requires a lot more of a “still” model as it were. I did, however, get this great 3D model of a plush fox by taking 32 still images and stitching them together in 3D using freely available software.

In the end, I bought one of those “clone a willy” kits. “Casting from life” as it’s called is usually done with alginate (the same stuff that’s used to make a mold of your teeth at the dentist). It’s body-safe, non-toxic and (unlike plaster of Paris) doesn’t heat up as it sets, but it also sets rather rapidly so you have to be quick. It’s also heavily reliant on water to keep its shape so you have to keep it well hydrated. I found that filling the negative mold with water and putting it in the fridge allowed it to last longer.

You have to get the temperature of the alginate correct (32 degrees C) whilst maintaining an erection, all within 2 minutes. It took a few goes, but I managed it (with a little help).

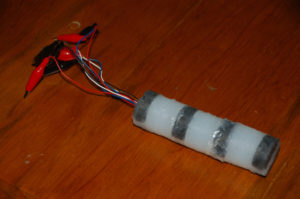

The other, most important part, was getting a protective layer of silicone around the sensing apparatus because I didn’t want little carbon fibres poking people in the butt. The sensing apparatus had now developed into a rather scary looking porcupine with 8 wires coming out of it, terminated by alligator clips.

Effectively what I am trying for is a process known as overmolding, where you mold a material over another to achieve the desired effect.

The silicone that came with the “Clone a willy” kit was a harder shore value than the silicone I already had, it was also much slower to cure. For this reason, when I poured it into the negative, it just pooled in the tip and didn’t really cover the sides as I hoped. So, I used my softer, faster curing silicone to coat the inside first, filled it with the (pink) harder silicone and then rammed the sensing apparatus down the center of the mold.

To be honest, I don’t think this is entirely the best approach and will need some re-thinking.

Once I hooked up the alligator clips to pins 4 through 11 on the MPR-121 shield, I was able to output tab separated values out onto the serial port. The Arduino software I am using conveniently converts those into a graph if you like.

The insertable test script is here. Note that I overwrote the initial voltage and threshold values in a bit of a brute-force manner because I didn’t want to mess with the existing cpp files that come with the MPR-121.

I get nice clean signals when I interact with ant part of the device, cleaner than I expected. My next challenge is interpreting all this data as “gestures”. I am thinking of getting information like % insertion, speed (rpm) and the kind of activity (e.g. touch, buttsex, handjob, blowjob, lick, squeeze, etc).

I think the dynamic time warp algorithm would be ideal for this kind of processing because not only could it match gesture curves without being time-based, the amount of “time warp” I get could tell me how fast the gesture is happening.

Of course, after I have done all this work, I discovered the concept of Swept Frequency Capacitive Sensing which could actually be the ultimate answer to my challenge. I guess we’ll see how we go!

Next: See how I implemented the gesture recognition for the insertable toy.

2 thoughts on “Insertable toy prototype”